In a letter published in the journal Nature, UC Santa Barbara mechanical engineer and materials scientist Jonathan Berger and his co-authors, UCSB materials and mechanical engineering professor Robert McMeeking and University of Virginia materials scientist Haydn N. G. Wadley, show that a supremely light and strong three-dimensional form that Berger conceived and named Isomax™ is the first to reach the theoretical bounds of performance.

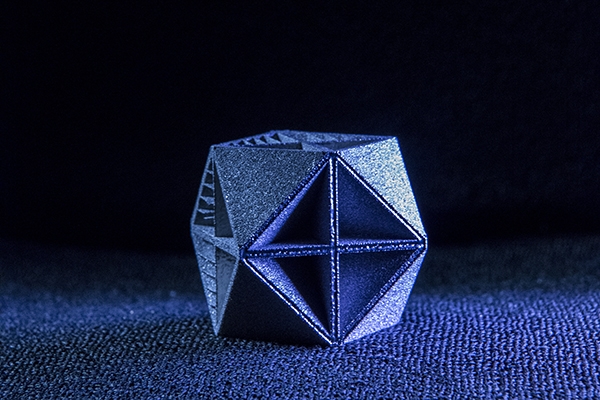

The beauty of this solid “foam” — defined here as a combination of a stiff substance and air pockets — lies in its geometry. Instead of the typical assemblage of bubbles or a honeycomb arrangement found in other foams, the ordered cells in Isomax are set apart by walls forming the shapes of tetrahedra and octahedra that transform an intersecting pattern of "cross" and diagonal walls in three dimensions. Berger explained that the combination of cells "resulted in a structure that is mostly air and is uncommonly strong for its mass."

“The Isomax geometry is maximally stiff in all directions,” Berger said. While other geometries, such as a honeycomb, can resist forces from one direction, force from a different direction can collapse them easily. Isomax’s cell structure enables the material to resist crushing and shearing forces without the need to make it heavier or denser.

McMeeking’s calculations also proved that, in the case of the lightest foams, the team was identifying the geometries that enabled them to achieve maximum possible stiffness.

“Isomax is going to be a very interesting metamaterial,” said Wadley. “It will be excellent for thermal insulating and sound absorption, and it could find application in aerospace structures, automobiles, and robotic machines.”

As resources become more limited and concern for energy efficiency grows, the value of a material with this mass-to-strength ratio increases, because it would require fewer resources to produce and less fuel to transport. The simple geometry makes it versatile, and, functionally graded, it can be used to create objects such as prosthetics and replacement joints, which need to have varying levels of stiffness within them.

Berger and his team are currently following up the study with experimental analysis while looking into manufacturing methods that may allow for efficient fabrication.

More information about Isomax can be found at Nama Development, a company Berger formed with the help of John Greathouse and UCSB’s Technology Management Program.

UCSB Researcher Jonathan Berger on The Most Efficient Material in The World from UC Santa Barbara on Vimeo.

3-D print of Isomax